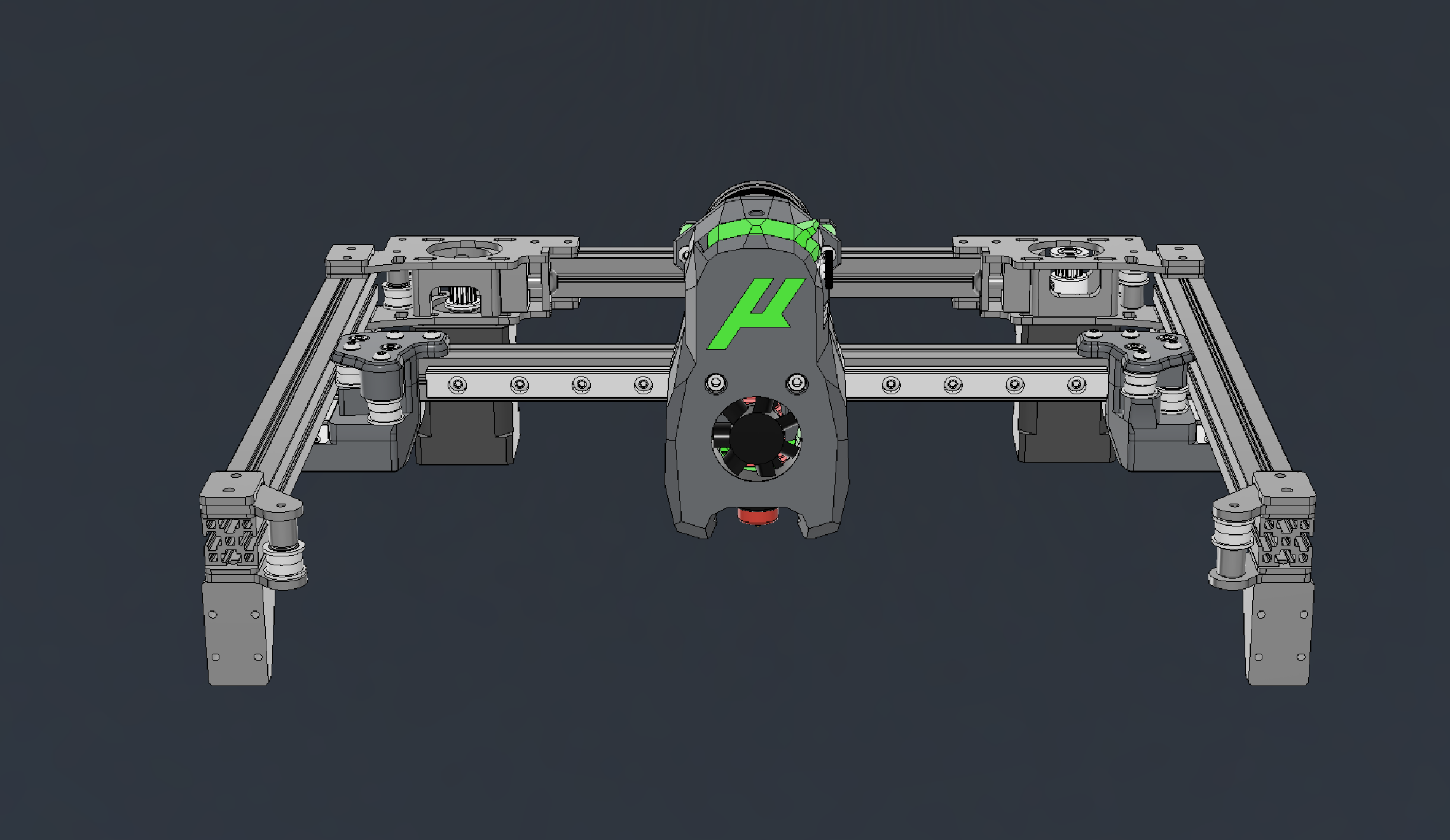

Micron Metal AB Drives

Getting Started

An offshoot of the AWD plates, this is just a shrunk down version to allow higher current to be run on Microns.

You can find the repo here: https://github.com/aTinyShellScript/metal_micron

But Why?

- Pros

- More Rigidity

- Cons

- You have to rebuild your gantry

Sourcing

Recommended Steppers:

- Moons MS14HS5P4200

- LDO LDO-35STH52-1504AH(VRN)

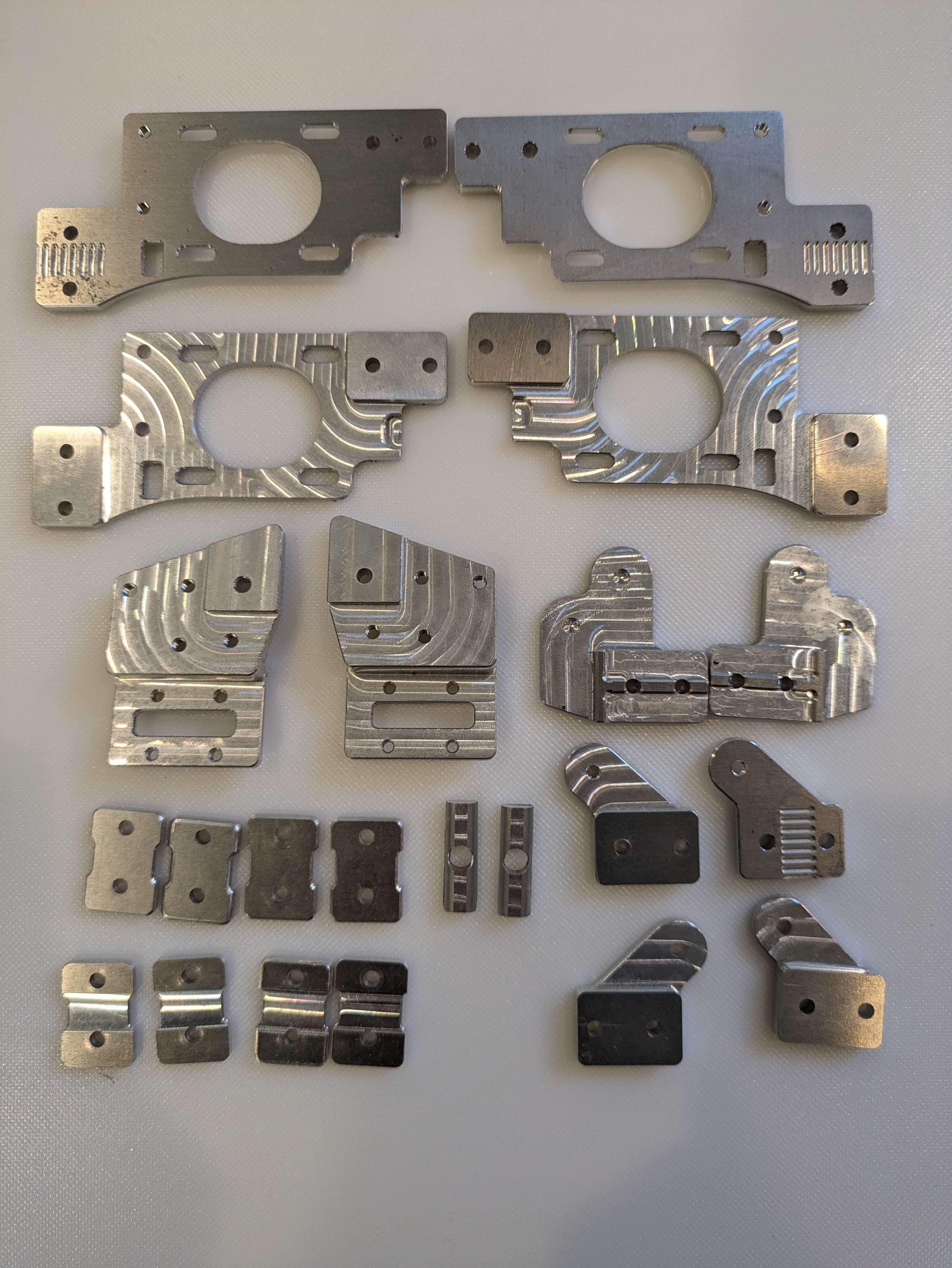

CNC Parts

If you want something nicer than lasercut plates, there is a CNC option developed by @DaveyR.

CNC AB Drives, XYjoints, Belt Clamps, and Idlers.

CNC AB Drives, XYjoints, Belt Clamps, and Idlers.

- US Vendor

- Talk with @DaveyR in the 'Metal Micron' user-project channel in the Armchair Heavy Industries Discord if you're interested in a full set.

Self-Sourcing

- Recommended plate material: 5052 Aluminum, 0.100"/~2.54mm

- Recommended spacer material: Anything, 0.059"/1.5mm

- Tapped will require you to tap 12 m3 holes. Two in each AB plate and 1 in each idler plate.

- Untapped will require a nylock nut to retain the bearing bolts.

- DXFs are available here if you want to use another manufacturer or cut them yourself.

Warning

SendCutSend will not cut the belt grip holes in anything thicker than 2.54mm. Check with other providers for their limits.

- US

- Europe

- China

Note

If you've got suggestions for additional vendors, please shoot me a message on Discord.

BOM

* 2x M5x20mm

* 2x M5 Nuts

* 14x M3x30mm

* 24x M3x12mm

* All stock bearings and shims

* 6x M3 Nuts (FOR UNTAPPED ONLY)

Printed Parts

You need to print all the bits in the root of the STL folder.

If you want to try out the Rigid Z Carriages:

- They are in the Optional folder in the STL folder.

- You'll need 8x M3x16 bolts and 8x M3 washers.

If you want to use the stock micron z-carriages:

- Print 8x of the 'Z_Tension_Clamps'.

Assembly

Use the CAD for info on how to assemble.

Bearing Stacks

Bearing stacks are identical to the stock micron.

Belt Pathing

Instead of the belt coming from the back to go around the stepper, it comes in from the side. See CAD.

Tensioning

- Loosen the 4 stepper mounting bolts slightly so the whole tensioner can move freely and move it to the slackest setting.

- If you do not loosen them enough, you WILL bow the tensioner plate.

- Ensure the belts are well secured and tensioned equally at the toolhead.

- Your belts should be equal in length and have the same amount of teeth sticking out past the toolhead.

- Turn the M5 bolt clockwise to increase tension to desired amount.

- Tighten the 4 stepper mounting bolts before testing.