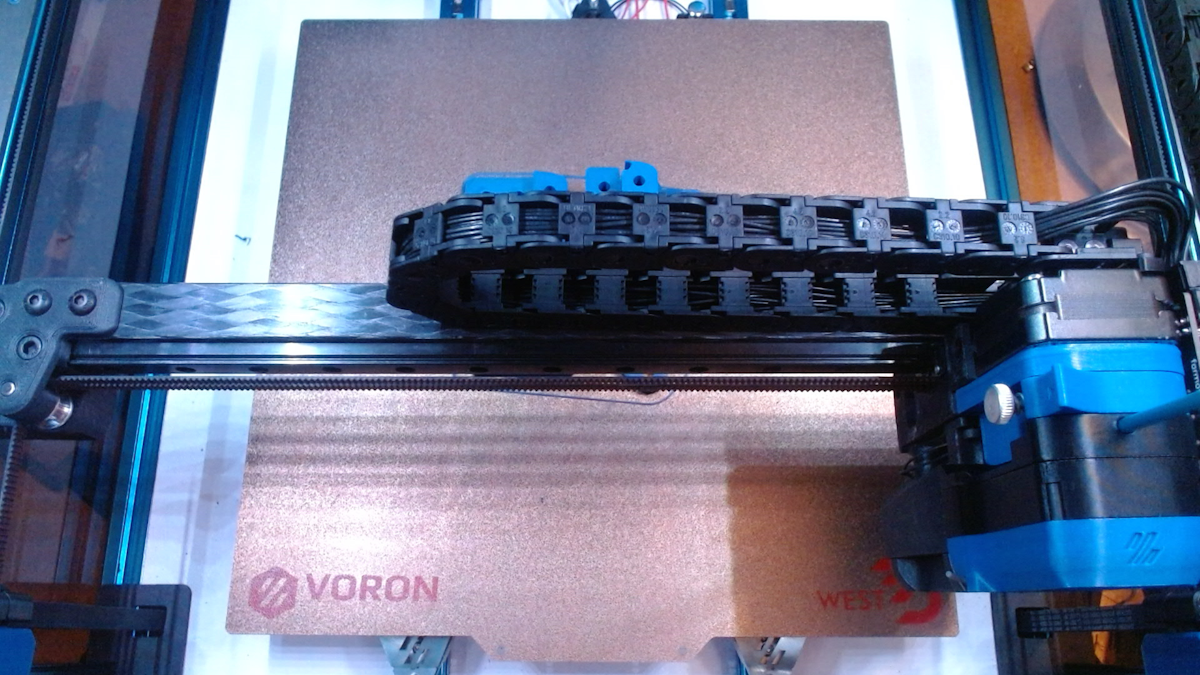

My First Mod -

This is an old mod but I'm keeping it here for posterity.

Getting Started

Ask yourself if you hate your lungs and feel like you're missing out when you hear mesothelioma commercials on TV.

But Why?

I saw it in a Josh Murrah video and wanted one.

- Pros

- Wicked cool, dude.

- +5HP to your printer

- 200g-ish of weight savings over a 2020

- Cons

- Silicosis

- Might get droopy in your chamber

- Weight savings isn't always the goal

Sourcing

BOM

- 20x20x18mm Carbon Fiber Square Tube

- 330mm for a 250mm bed size

- 380mm for a 300mm bed size

- 430mm for a 350mm bed size (20x20x17 is recommended for a 350mm printer, to reduce flexing.)

- ⚠️Do not buy pullstruded tube for this⚠️

- 6x M5 tnuts

- 7-10x M3 Flanged Locknuts

- 7-10x M3x10 Socket Head Cap Screws (Rail mounting)

- 4x M5x12 Button Head Cap Screws (Top XY Joint)

- 2x M5x30 Button Head Cap Screws (Bottom XY Joint)

- Blue (Medium) Loctite

Optional: - 2x M3 Heatset Inserts for Cable Chain mount - 5mm OD Carbon Fiber Tube or Rod - 4x cut to 40mm

Tools

- Mask or Respirator

- Don't breathe in carbon fiber dust, please.

- Safety Goggles

- Drill Press

- Don't use a hand drill.

- Drill Bits:

- 'Small': 3.5mm OR 1/8"

- 'Large': 6.5mm OR 1/4"

- Hex Drivers

- 2.5mm for M3

- 3.0mm for M5

- Saw

- If you're going to use a hacksaw, a mitre box can help keep your cut straight.

- A mitre saw is the best way to go, if you have a blade that will work.

- Fine Grit Sandpaper

- Blue Painters Tape

Warning

Carbon Fiber dust will fuck you up. Always wear a mask or respirator. Do any work on it outside.

Tips for Working with Carbon Fiber

- Use a fine/extrafine toothed saw blade.

- Use carbide tipped drill bits. HSS bits will wear out quick.

- Run your drill press at high speed (3000-5000rpm) and cut slowly, using low pressure.

- Cover the area you are going to cut in blue painters tape to help avoid delamination.

- Use sandpaper to smooth out the edges of the cut.

Instructions

Printing instructions

- Normal Voron print settings.

- You can drop the infill percentage on the inserts if you want as the 4 perimeters are what take the load.

- Print a set of Inserts.

- If you're going to use cable chains, be sure to print the correct insert with support for heatsets.

- Print a set of XY joints.

- Use the Pinned set for the Hartk pins mod or if you're going to use carbon fiber pins.

- You can't reuse your existing ones as they have bits that are designed to go into the slot of a 2020 extrusion.

- Print 2-3 MGN12H rail positioning tools.

Insert Assembly

- Slide an M5 tnut into each hole.

- With an M5 bolt holding the tnut in place over the hole, use tools to spin the tnut 90 degrees.

- (Optional) Insert the M3 heatsets if you are using them.

XY Joint Holes

- Cut your CF tube to size. For a 300mm sized 2.4/Trident, that is 380mm.

- Unless you're very confident in your ability to cut square, cut it a little long and use a sanding block to get it to the correct length.

- Use a straight edge to identify the flatest face.

- Mark this face, it will be the one the rail is mounted to.

- Apply blue painters tape to the top and bottom ends of the tube.

- Measure and mark 7.65mm and 23.15mm from both ends on the top of the tube.

- Measure and mark 7.65mm from both ends on the bottom of the tube.

- Find and mark the center of these points.

- You can use your rail and the centering tools to do this.

- ⚠️Put on your mask! Don't inhale carbon dust, it is not good for you.⚠️

- Using the 'small' drill bit in a drill press, drill pilot holes at your marked points.

- Drill your final holes using the 'large' drill bit.

- Using an oversized drill bit will give you wiggle room in case your measurements are a bit off.

- (Optional) If using cable chains, use your insert as a template for where to drill the mounting holes.

- Use the 'small' drill bit for these holes. You can use a slightly larger bit if you think you need wiggle room for mounting.

Rail Holes

- Install the inserts on the correct sides and attach your XY joints, temporarily. Do not install the idlers and bolts/pins.

- Apply blue painters tape to the face of your tube.

- Using the centering tools, set your MGN12H rail on the face of the tube, centered between the two sides.

- Use blue painters tape to secure the rail to the tube, to stop it from moving side-to-side.

- Either mark your holes or use the rail itself as a drill guide.

- You only need a bolt in every other hole. If you start from each side, you'll end up with two side by side in the middle on a 350mm rail.

- Drill your holes with the 'small' drill bit. No need for a pilot hole.

- Clean up.

- Remove and clean rail

- Remove XY Joints

- Remove inserts

- Remove all tape

Attaching Rail

- Using the centering tools, set your MGN12H rail on the face of the tube and align with the drilled holes.

- Insert nuts into the Nut Holder and press them firmly into it.

- Use pliers to fully seat the nuts into the holder, otherwise it will not fit into the tube.

- Slide the Nut Holder and Spacer into the tube, aligning them with the drilled holes.

- Using Blue Loctite, screw in M3x10 bolts and tighten.

- Remove the spacer and press down on the nut holder. It should pop off the back of the nuts.

- Using a hex driver or something flat may be needed to pop it off the last nut.

- If you need to remove your rail, you will be able to use the nut holder and the spacer.

- Repeat for the other side of the rail.

Carbon Fiber Pins

- Wear your mask and goggles.

- Cut pins to 40mm.

- You may want to cut them a bit long (41mm) if you are using tube, so you can pull them out without splitting the XYjoint.

- Lightly bevel the edges with sandpaper.

Questions

Just buy an x-tube. Don't make this.